Butterfly valves are requisite in applications where tight shut-off is needed.

Butterfly valves are a family of quarter-turn rotational motion valves that are used in pipelines to shut-off flow. The disc opens and closes with a low-torque rotation of 90 degrees.

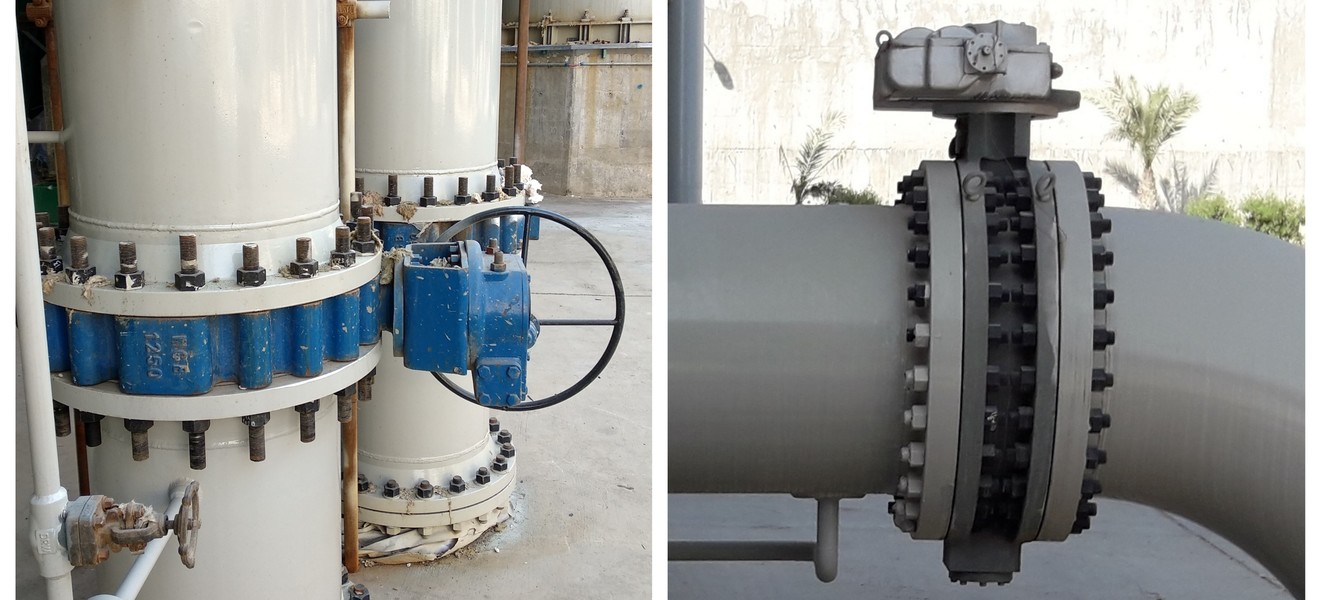

The entire valve is made up of a valve body, disc, stem, seat, and use handles, gears, or automatic actuators for operation.

For low-pressure and non-critical applications, API 609 Centric Butterfly Valves (soft seated) are preferred over gate valves and ball valves because they are less expensive, lightweight, and easier to install.

Butterfly valves have a wide range of uses, for a wide variety of uses for municipal water supply, industrial and sanitary applications, HVAC systems, slurries, and beyond. Butterfly valves are commonly used for flow regulation in large-diameter pipes.

With the emergence of double and triple eccentric designs, butterfly valves are increasingly being utilized in the oil and gas industries and have begun to compete with more traditional valves such as globe valves and ball valves.

There are three main types of Butterfly Valves;

Concentric Butterfly Valve (Centric); These valves are designed to solve the tightening problems that can occur between the disc and seat of the butterfly valve. The stem and disc of the valve are situated in the center, and it creates a seal when the disc deforms the soft seat, causing full friction during the whole operating cycle. The concentric butterfly valve is commonly found in water distribution and wastewater treatment plants, fire control systems, and gas supply lines, installations including Filter Installations, Pumping installations.

Double Eccentric Butterfly Valve; The double-offset structure features the stem center deviated from the center of the disc and valve. With this structure, the valve disc can leave the valve seat quickly, greatly reducing unnecessary over-compression and scraping between them. Double eccentric butterfly valves are widely used in subsurface water supply applications and as compared to gate valves (particularly in larger bore diameters) because they are lighter, less expensive, and require less excavation.

Triple Eccentric Butterfly Valve; The triple offset design eliminates the rubbing between the seat and seal ring through the flow path, reducing seat and seal wear and extending cycle life. Triple offset butterfly valves are made of high-quality materials such as stainless steel, duplex, and super duplex steel, and they compete with ball valves in critical applications due to their high temperature and pressure and resistance to corrosion.